|

|

||

|

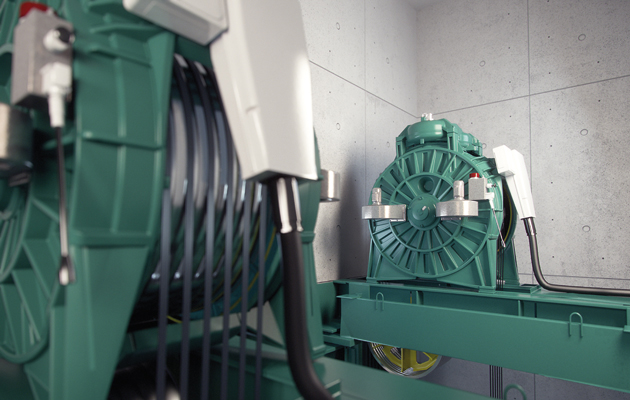

Sometimes it is the unexpected or overlooked that can have the greatest impact. UltraRope is a new carbon-fibre cable for lift shafts that could revolutionise our skylines, and possibly even our journeys through space … The maximum height of a standard steel-rope elevator is 500 to 550m, a limit set by the rope. Steel is tough but it’s also heavy, and enough of it for a 500m lift shaft weighs more than 20,000kg – weight that must be born by the same rope. It can be reinforced by adding more steel, but that just adds more weight, so you’re caught in an exponential trap as the law of diminishing returns grinds away. As well as weight, more steel means more bulk, larger coils of rope, more powerful machinery, more power … for all intents and purposes 500m is an impermeable practical limit. This limit has so far been overcome by a different kind of brute force: adding more elevators, linked by sky lobbies. But this replaces a technical limit with a human one: impatience and inconvenience. “In order to go to the top of the highest buildings you need to take three different elevators,” says Giuseppe Bilardello, head of research and development at Finnish lift company Kone. “We cannot build elevators that can go from ground to top in one go. UltraRope will enable that.” The product, launched last year, doesn’t really look like rope at all, but a flat-sided, black strip that, in the words of Kone’s own magazine, resembles liquorice. This “rope” derives its strength from carbon fibre, a miraculous material at last being put to a better use than overpriced suitcases for the rich. Binding the carbon-fibre strands is a polyurethane-resin coating, which provides the friction needed to grip to the lift mechanism properly, aided by the rope’s flat sides. This slimmed-down strip delivers the strength of steel for less than a fifth of the weight. And the impact could be profound. The 500m limit is smashed: UltraRope makes a kilometre-long elevator shaft a possibility, bringing a new generation of super-tall buildings a stride closer. Already, the new system has been commissioned for the Kingdom Tower now under construction in Saudi Arabia – which, when complete, will be the world’s tallest building. It creates what Bilardello calls an “open spectrum” of possibilities for engineers and designers. There are other limiting factors on tower height, but this was a big one, and now it’s gone. |

Words Will Wiles |

|

|

||

|

This size of the plant at the top of buildings can be significantly reduced |

||

|

Cutting the steel cord has other significant benefits. UltraRope’s lightness means that elevator systems will consume less energy: 15 per cent less over 500m, rising to 45 per cent at 800m. With less lifting power needed, the elevator plant at the top – made such a familiar sight by Bruce Willis and his action-movie colleagues – will be smaller and lighter. Less load will be placed on the building’s structure; the mobile mass in the shaft will be lighter by a factor of “almost 15”. UltraRope is not as susceptible to “sway” caused by the movement in the building frame, for instance from the wind. And lastly, it is more hardwearing than steel, does not rust or stretch, and is calculated to have a lifespan twice that of cables. Development of UltraRope took nine long years. “The biggest challenge was testing, because you need to be 100 per cent sure that that everything is working today and later,” Bilardello says. “For testing, we have physical machines that are going up and down 24-7.” Much of this testing takes place at Kone’s high-rise laboratory at Tytyri near Helsinki, which possesses its own 305m shaft. Bilardello is tight-lipped about what approaches the company has had from architects and engineers wanting to exploit the radical potential of UltraRope. But he does say that there has been a great deal of interest concerning the renovation of existing buildings, and “contact” with other industries where a replacement for steel cable might be useful. The Economist magazine even suggests that UltraRope might be a suitable material for a space elevator, a (comparatively) cheap way to boost people and materials into orbit. In the meantime, UltraRope’s immense contribution to the possibilities of terrestrial architecture has landed it a place in the Victoria & Albert Museum’s Rapid Response Collecting gallery. Listen to Roma Agrawal, engineer at the Shard, discussing lifts to space |

||

|

Kilometre-long elevator shafts are now possible |

||