|

|

||

|

Finnish glassmaker Iittala is renowned for producing works by Alvar and Aino Aalto, Tapio Wirkkala and, most recently, the Bouroullecs. But it is the factory workers, performing one of the most intuitive crafts in the world, who bring their designs to life As I walk into Iittala’s picturesque, snow-covered glassworks factory a 90-minute drive from Helsinki, I’m presented with a wondrous and incongruous scene: a circular platform filled with red-hot fiery furnaces and a series of working stations inhabited by men who could easily be mistaken for car mechanics. Wearing well-worn jeans and polo T-shirts, impassive expressions and, in some cases, headphones or wraparound mirrored shades (the latter, I later discover, are not so much a fashion statement as necessary protection against the brightness and heat of molten glass), they slowly produce one delicate and beautiful glass object after another. Iittala is one of the best-known high-design glass and tableware manufacturers in the world. Think of it, and objects dating back decades come to mind: the sinuous and serene Alvar Aalto vases created in 1936; the stackable glasses designed by Aalto’s first wife Aino in 1932; Tapio Wirkkala’s Ultima Thule series of glasses and bowls from 1968, inspired by the melting ice of Lapland; or Kaj Franck’s functional and playful Teema plates and mugs, designed in 1952. All are, remarkably, still in production and have become design classics. When people own an Iittala vase or product they rarely throw it out or give it away.

About 65 blowers work on the Iittala site in Hämeenlinna

Stickers being applied to a completed Ruutu vas The Finnish company’s theatrical “hot shop” is where its 65 or so glass-blowers take turns shaping, blowing and moulding hot globs of glass on pipes at least 5ft long. The scene is loud and messy but I soon realise it has a rhythm and pace to it. “When you first see the hot shop it looks chaotic,” agrees Harri Koskinen, who has been Iittala’s design director since 2011. “But it isn’t. Everyone knows what they are doing, everybody has their own routine and their own specific tasks to carry out.” The glass-blowing process is a highly choreographed process that involves up to seven people and includes several critical moments, all completed by hand. It is also one of the most intuitive and unforgiving crafts in the world. “There are no books you can read,” says Per-Henrik Hagberg, Iittala’s factory director. “It’s all about touch and knowing.” It’s also mesmerising to watch. At any one time, several glowing hot globules of glass are moving around the platform in a dizzying display. Younger blowers, known as post boys, gather the molten glass (a mixture of sand, sodium and calcium carbonate heated to a terrifying 1,450ºC for 24 hours) from the furnaces on to a blowpipe and sit down on a wooden bench as they blow lightly into the orange-hued mass and shape it with the help of an oversized wet wooden ladle. “Even the first small air bubble has to be really symmetrical and well balanced,” explains Koskinen. Achieving walls of even thickness in a glass product is “very challenging even for the most experienced blowers,” he says.

The glass is shaped and given texture with the aid of a wooden paddle

The glass blowers use traditional methods honed over generations Next up, the experienced blowers, who stand closer to the centre of the platform, continue to shape and build the globule, turning and lifting the pipe before blowing inside it. The master blower then gives the mass of glass texture with the aid of a wooden paddle and a wad of wet newspaper or cellulose board, pressing or kneading it to the right proportions. The glass is placed into a steel mould (wood moulds were used in the past but abandoned as they have a limited life) and blown into its final shape. Finally, the glass is set down on a mechanical rotator over a flame that reduces any tensions, and then a “carrier” brings the piece – replete with its “hood”, which will be later lopped off with the aid of a grinder – to an annealing kiln to cool. “When glass cools down, it shrinks and can break, so we need to control the cooling and do it very slowly for anything from two to 36 hours,” Hagberg says. If the blowers (some of whom are fourth-generation and have been here for more than 40 years) didn’t know exactly how to manoeuvre their blowpipes, or when to stop twirling, coaxing or shaping the hot molten glass, serious accidents could happen and far more objects would end up in the reject pile because of bubbles and impurities. “Glass is not fragile when it’s hot but it is fluid, liquid and alive,” explains Koskinen. “You need to be sensitive with the material and understand how to move your body since it follows every gesture you make.” And you need to do all this in temperatures that most people would find debilitating. He continues: “The heat from the glass is astounding. Your body really needs to adjust to it.” Workers have to take frequent breaks and can often be seen leaning against long white vents that spew out cool air.

Workers wear wraparound shades and protective sleeves to shield them from the light and heat

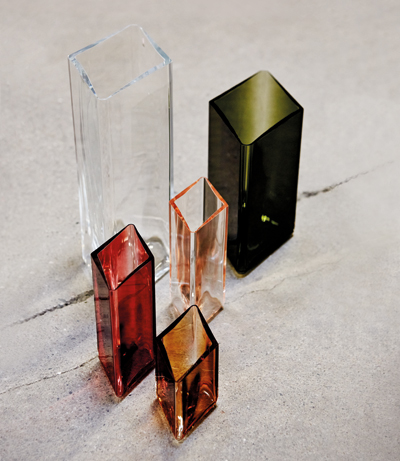

Behind the scenes in the factory One of Iittala’s latest designs is a collection of ten vases by French brothers Erwan and Ronan Bouroullec. Two years in the making, and honed down to their most simple form, the Ruutu vases have the potential to become the next classic product for the company. Like Aalto’s 1930s vase, their simplicity is deceptive, and it actually takes seven craftsmen to make a single piece. But, unlike the curvaceous Aalto vase, Ruutu is all angular shapes and reflective facets and geometries. The Ruutu collection also shows off why Iittala is considered a leader in the world of coloured glass. Sporting a palette of seven delicate aquarelle tones including cranberry red, moss green and salmon pink, and coming in five sizes, the vases strike an elegant pose on their own but – like most Iittala products – are designed to be combined and assembled with other pieces in the range. When placed against one another, new hues are created. “We introduce one or two new colours a year,” Hagberg says, “and have an active colour palette of about 100 colours.” In 2015, the company introduced Desert, a warm amber brown that it says is a nostalgic reference to hot childhood summers and to Iittala glass ranges from the 1950s. In 2016, it will add a green. “In general, the warmer the colour, the more expensive it is to make,” Hagberg adds.

A Ruutu vase is gently inserted into a steel mould

Measuring devices for the Ruutu collection Partly this is because warmer colours such as orange, red or yellow require more steps than other colours and a more complicated heating and cooling sequence to bring about the necessary chemical reactions; partly it’s because warmer colours take on their final colour only after the cooling process. “When you are handling red glass out of the furnaces it looks blue-ish,” Koskinen says. “Whereas colours such as green, blue or grey can be seen even at the hot shop stage.” Most of the designers who have created pieces for Iittala have a vision of what they want before they enter the factory, Koskinen says. They will visit and test shapes with the blowers but their concept remains largely unchanged. Not knowing a huge amount about the glass-blowing process – and its limitations or constraints – can be liberating, says Koskinen. “You need to break the rules in order to achieve something that has not been done yet,” he says. Occasionally, the blower becomes the co‑designer, however, as was the case with Koskinen’s own Art Works collection of limited-edition glass objects for Iittala in 2004, where one of the pieces – Uusi Alue – was shaped by the blower’s hand without the use of a mould. Like many historic companies in the globalised design world, Iittala is now part of a wider group and has set its sights on new markets.

Vases from the Ruutu collection by Ronan and Erwan Bouroullec, 2015 In recent years it has expanded into Asia with store openings in Japan, Korea, Taiwan and China. Next, the company plans to make inroads into North America. All the blown-glass production still takes place in the original Iittala factory, however, founded in the town of Hämeenlinna in 1881. In past years, Iittala has subsumed other historic glass factories (including the Nuutajärvi facility that predates the Iittala one by more than 100 years) and been bought up by various groups, including Finnish cookware brand Hackman in 2000. In 2007, the Iittala Group was bought by 366-year-old Finnish industrial powerhouse Fiskars, world famous for its ergonomic orange-handled scissors and also a manufacturer of everything from gardening shears to craft punches. Acquisition by Fiskars has meant a multi-million investment in Iittala, explains Hagberg, and many improvements to the climate and working conditions in the factory. The smaller glassworks at Nuutajärvi, located some 60km away, where all of Oiva Toikka’s famous birds were made until last year, was closed – not without controversy, though many of its workers were re-employed at the Iittala site. Glass-making has now been centralised in Hämeenlinna, which is the only glassworks still left in the area. There are about 200 workers on site, as well as a new fully automated batch house. In the past, raw materials were mixed in Nuutajärvi and then transported to Iittala in a long-winded process.

Tapio Wirkkala’s Ultima Thule of 1968 references the melting ice of Lapland

A selection of Oiva Toikka’s birds, designed in 1972 The refit at the Iittala site has also meant the creation of a new visitors’ entrance for the factory and a theatrical viewing balcony over the mouth-blowing section. A canny move, it makes visitors feel like the privileged audience to an industrious production of the craft of glass-making. Koskinen says he thinks the workers enjoy it too. “They get to show people they are masters of the glass!” he laughs. Before leaving, we have a chance to make our own Iittala vase. A ball of steaming molten glass at the end of a pipe is brought over and placed in a wet wooden mould. Keijo Kopra, a glass blower at the Iittala factory for 46 years, stands beside me and encourages me to blow and turn the pipe “slowly, slowly, slowly”. I feel a deep anxiety creeping in and keep having to take in gulps of air. The results are deemed “OK” by the inscrutable Kopra but, then again, I have done only a tiny fraction of the glass-making dance. While undoubtedly repetitive work for the blowers, the results are nothing short of alchemy. |

Words Giovanna Dunmall

Photography Mikko Ryhänen

Above: Glass furnaces work 24 hours a day |

|

|

||