In a future-focused research project, Caon Design Office and Woolmark have unveiled Modulo – an innovative seating concept centred around circularity.

Modulo by Cain Design Office is an aircraft seating research project carried out in partnership with the Woolmark Company. @caondesignoffice

Modulo by Cain Design Office is an aircraft seating research project carried out in partnership with the Woolmark Company. @caondesignoffice

With the aviation industry in urgent need of change, if it is to hit the net-zero 2050 goal laid out by the UN’s International Civil Aviation Organisation (ICAO), design studios and manufacturers are looking at a vast array of solutions to help carve out a greener and less carbon-intensive future. While experts state that the majority of the needed change lies within the shift towards Sustainable Aviation Fuels (according to IATA), there is also a spotlight being placed on the cabin interiors themselves. In reducing the weight of fixtures and fittings, alongside a modular design sensibility to minimise waste when refreshing airline interiors, it all helps to contribute towards the reduction of the industry’s carbon footprint.

Aligned to this much-needed monumental shift, a recent collaboration between multi-disciplinary creative practice Caon Design Office and The Woolmark Company is presenting a new vision for cabin seating with modular configurations and renewable materials being a primary focus for the research project. Titled Modulo, the result is a standalone seating module that prioritises circular design values and the passenger’s wellness and comfort. With an organic form, the enclosed compartment is reminiscent of First-Class arrangements but is designed to not be confined to a particular category.

With a lightweight frame and 3d knitted wool membrane, Modulo prioritises the passenger’s wellness and comfort alongside circular design values. @caondesignoffice

With a lightweight frame and 3d knitted wool membrane, Modulo prioritises the passenger’s wellness and comfort alongside circular design values. @caondesignoffice

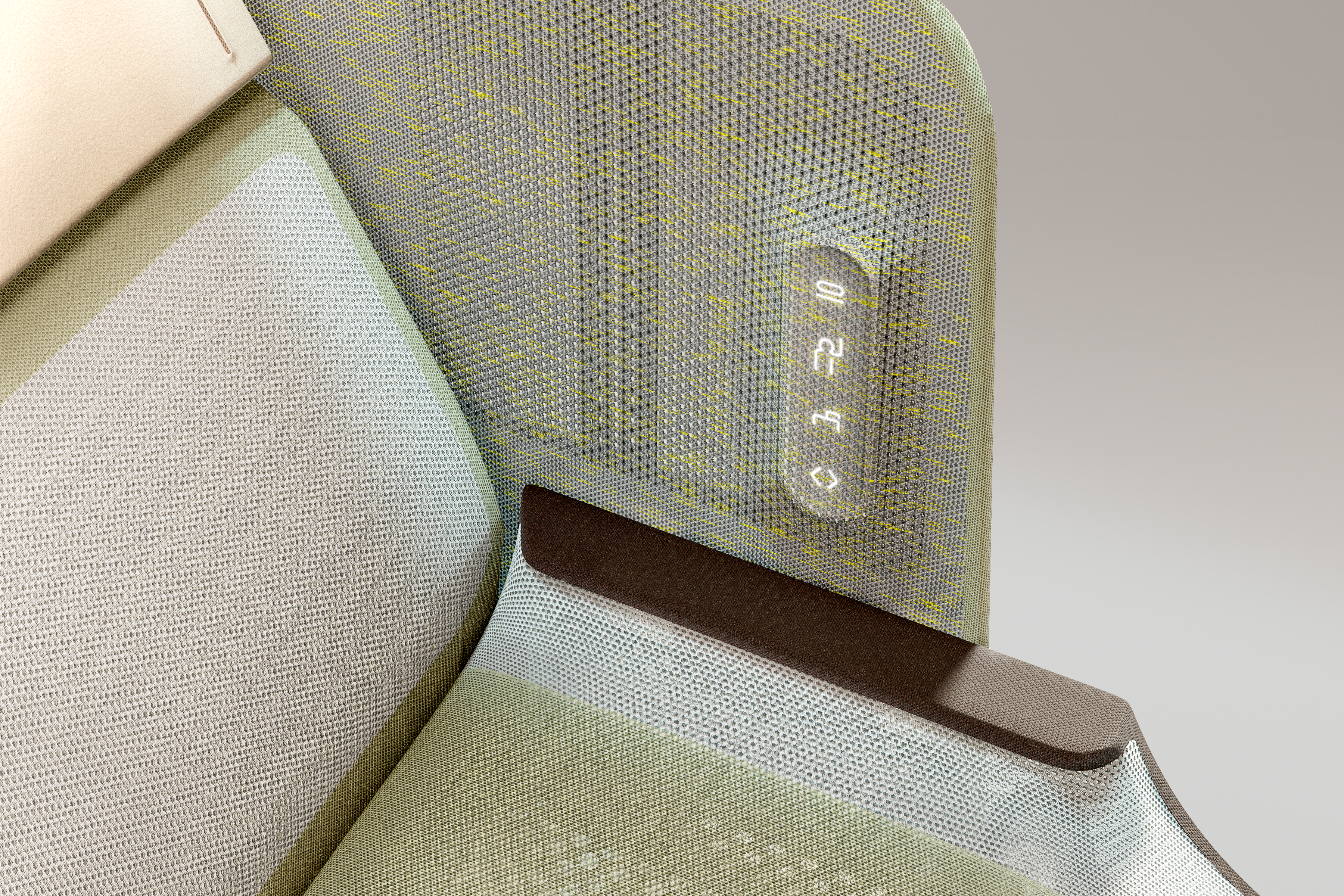

The pioneering model consists of a titanium, aluminium, and carbon fiber frame which is clad in a semi-transparent 3D knitted wool membrane, offering structure while being flexible enough to mould to the organic silhouette of the pod. Constructed from Australian Merino Wool, the unique selection of this natural, biodegradable, and renewable fibre was largely down to its wide array of benefits. “By harnessing the benefits of Merino wool, such as breathability, moisture-wicking properties, and luxurious softness, Modulo demonstrates how Merino is uniquely positioned to elevate the future of travel through unparalleled comfort and enhanced sustainability,” states John Roberts, the Managing Director of Woolmark. “This collaboration with Caon Design Office underscores a shared commitment to driving innovative solutions with eco-conscious design principles.” With the ultralight nature of the materials also helping to keep weight to a minimum, the selection of responsible materials continues into the wadding which can be strategically integrated within the seat thanks to the knitting technology used and therefore reducing the reliance on traditional foam fillings – fraught with recyclability issues due to its chemical content.

Thanks to a quick-release mechanism, the knitted wool membrane can be easily interchanged when a cabin refresh is needed. @caondesignoffice

Thanks to a quick-release mechanism, the knitted wool membrane can be easily interchanged when a cabin refresh is needed. @caondesignoffice

With the wool membrane being a primary touchpoint for users, elevating the experience with its sumptuous tactility, the unit’s modularity is another defining feature. Aided by a quick-release mechanism, the skin can be easily interchanged allowing for a cabin refresh to occur without replacing the entire framework within. Introducing such ease and speed into cabin overhauls is critical in creating a more sustainable future for the sector while also ensuring the interior environment can remain up-to-date and aligned to a more satisfactory user experience.

The 3D knitted wool membrane also becomes the touchpoint for users helping to elevate the experience with a luxurious tactility. @caondesignoffice

The 3D knitted wool membrane also becomes the touchpoint for users helping to elevate the experience with a luxurious tactility. @caondesignoffice

While Modulo remains very much a theoretical concept at this stage, David Caon, the creative force behind the Australian studio, says there has been much excitement about the project from within the industry. “Many liked how it contributed to the passenger’s wellness and comfort as well as the functionality of the rapid refresh idea,” he reveals. “However, meetings with the engineers resulted in a number of raised eyebrows across the table – mostly due to certification barriers which would occur if placed within an aircraft today.” With the key factors being materiality, form and technology, the standalone configuration is also very unlikely to be adopted by airlines with most current seating placed together in integrated nests to maximise the available floor space – another challenge when looking at the commercial viability of the project. “The realities of a typical commercial aircraft fitout program are such that Modulo would need some development time outside of a specific project,” Caon continues. “Nevertheless, the thinking around Modulo is, in fact, bigger than just the airline industry and could be adapted to any form of mass transport, possibly even space travel in the not-so-distant future.”

While only a research project, could concepts such as Modulo allow us to envision a new future for the aviation sector. @caondesignoffice

While only a research project, could concepts such as Modulo allow us to envision a new future for the aviation sector. @caondesignoffice

As design studio’s such as Caon continue to explore thought-provoking solutions to help address the environmental issues within the industry today, it does offer a glimmer of hope in understanding that change is possible. With the shift towards a circular design model an absolute must for the industry, added to an individual responsibility to reduce air travel where possible, the timing of such change is posing to be the biggest challenge. “It’s alarming to think of how little time aircrafts actually spend on the ground,” says Caon. “It makes the opportunities to refresh and repair worryingly few and therefore expensive. Improvements in manufacturing technology, however, with the increase in accessibility of more specialised materials and rapid processes will help bring this about. And it will require designers and engineers to think in a modular way and work towards reducing complexity.” So, as this project showcases, with a future-focused vision and a shift towards modularity on a widespread scale, could the 2050 net-zero goal still become a reality? Only time will tell.

Discover more on the work of Caon Design Office here.

Get a curated collection of design and architecture news in your inbox by signing up to our ICON Weekly newsletter